PRODUCTS CENTER

view moreDouble the cost-efficiency with diameters up to 65 mm

The no. 1 for parting off operations up to 200 mm

DO-GRIP – The One and Only Double-Sided Twisted Parting Insert with no Depth of Cut Limitation

Deeper Grooving

Flat Top Blades with 4 Pockets Shank Tools with 2 Pockets

Pentagonal TANG-GRIP Adapters with 5 Pockets for TAG 2 & 3mm Widths

Groov·tec™ GD – double serration, double secure.

For higher cutting parameters and maximum process safety

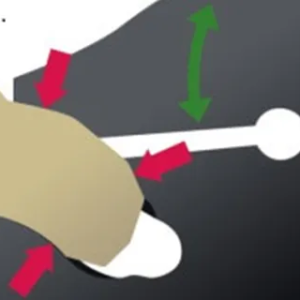

Walter Groov·tec™ GD is probably the most process-reliable tool system for grooving and parting-off as well as recessing and copy turning currently available on the market. Suitable for grooving depths of up to 1.024 in (26 mm) and universally applicable on lathes of all kinds, Groov·tec™ GD is characterized above all by its unique insert clamping: The cutting inserts, which are double serrated from both top and bottom, are absolutely secure against being pushed out of the insert seat from the side, thereby ensuring maximum precision and process safety. The stability of the system, together with Walter precision cooling, ensures a 50 % longer tool life and the best machining results.

Stable Groov·tec™ GD serration profile

Stable Groov·tec™ GD serration profile

for maximum process reliability and 50 % longer tool life

Higher cutting parameters

Higher cutting parameters

thanks to double-serration profile and Walter precision cooling

Maximum productivity and tool life

Maximum productivity and tool life

- thanks to wear-resistant Tiger·tec® Gold grades

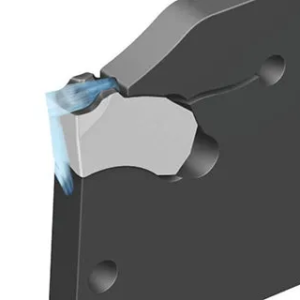

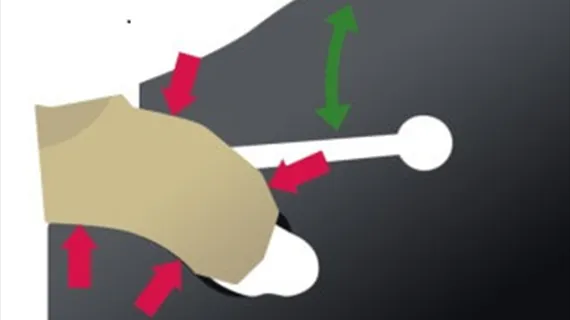

Walter Cut DX – with “SmartLock”

First choice for parting off diameters up to 1.378 in (35 mm)

Thanks to its unparalleled handling benefits, the DX system is unlike any other currently available parting off system for Swiss type auto lathes and multi-spindle machines – especially where space is limited: The screw connection for insert clamping is fitted to the side instead of the usual position on the top (“SmartLock”). Only DX makes it possible to change the inserts in the machine. Because of this, the system does away with most of the change time. Attaching cooling hoses further amplifies this effect.

Reliabl

Reliabl

thanks to patented positive-locking design: No incorrect fitting of the cutting insert, particularly for small insert widths

Tool change time reduced by 70%

Tool change time reduced by 70%

thanks to simple insert changeover in the machine with SmartLock

Increased cutting parameters and longer tool life

Increased cutting parameters and longer tool life

- thanks to new, more stable insert clamping

Walter Cut GX – the universal system

Double the cost-efficiency with diameters up to 65 mm

The wide range of double-edged indexable inserts makes the GX system the first choice for cutting depths up to 33 mm and parting off diameters up to 65 mm. These inserts are available in various different versions: In the form of monoblock tools, reinforced parting blades, with a Walter CaptoTM interface or as boring bars – with or without precision cooling. Grooving, parting off, internal recessing: Everything is possible with the Walter Cut GX universal system – axially and radially, in virtually all ISO materials.

Wide selection of chip formations and grades –

Wide selection of chip formations and grades –

the right cutting tool material and chip formation for any application

Double-edged grooving system –

Double-edged grooving system –

with cutting depths up to 33 mm

Radial, axial and internal machining –-

Radial, axial and internal machining –-

- all with the same cutting inserts

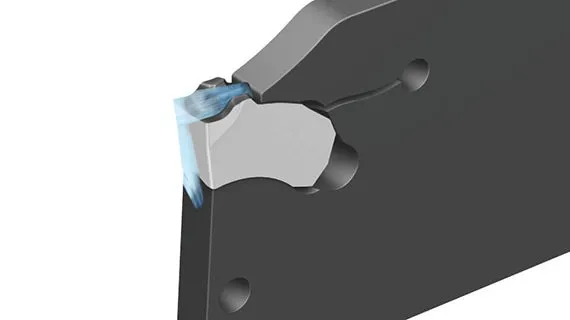

Walter Cut SX – for large diameters

The no. 1 for parting off operations up to 200 mm

A self-clamping grooving system is indispensable wherever large cutting depths are required (≥ 33 mm). The single-edged Walter Cut SX system is the right choice here. Ideal for parting off applications with large diameters up to 200 mm – and, thanks to Tiger·tec® Silver PVD and CVD grades, can be used in steel, stainless steel and materials with difficult cutting properties, as well as for machining cast iron (also for non-ferrous metals in the uncoated version).

No loss of the cutting edge during machining

No loss of the cutting edge during machining

due to the optimal, positive-locking self-clamping system of the insert seat

Optimised chip formation types

Optimised chip formation types

for various applications and precise coolant supply

A single cutting insert

A single cutting insert

for parting off and slitting, resulting in lower inventory costs

Flyer Online catalogue

Careers

Become one of us!

When you join our global team, you will experience a culture that enables important shifts.

Sustainability

Our sustainable future

We want to be a positive force in shaping the future of industry and leading the way with innovation and engineering for the world we need.